INSTRUCTIONALS

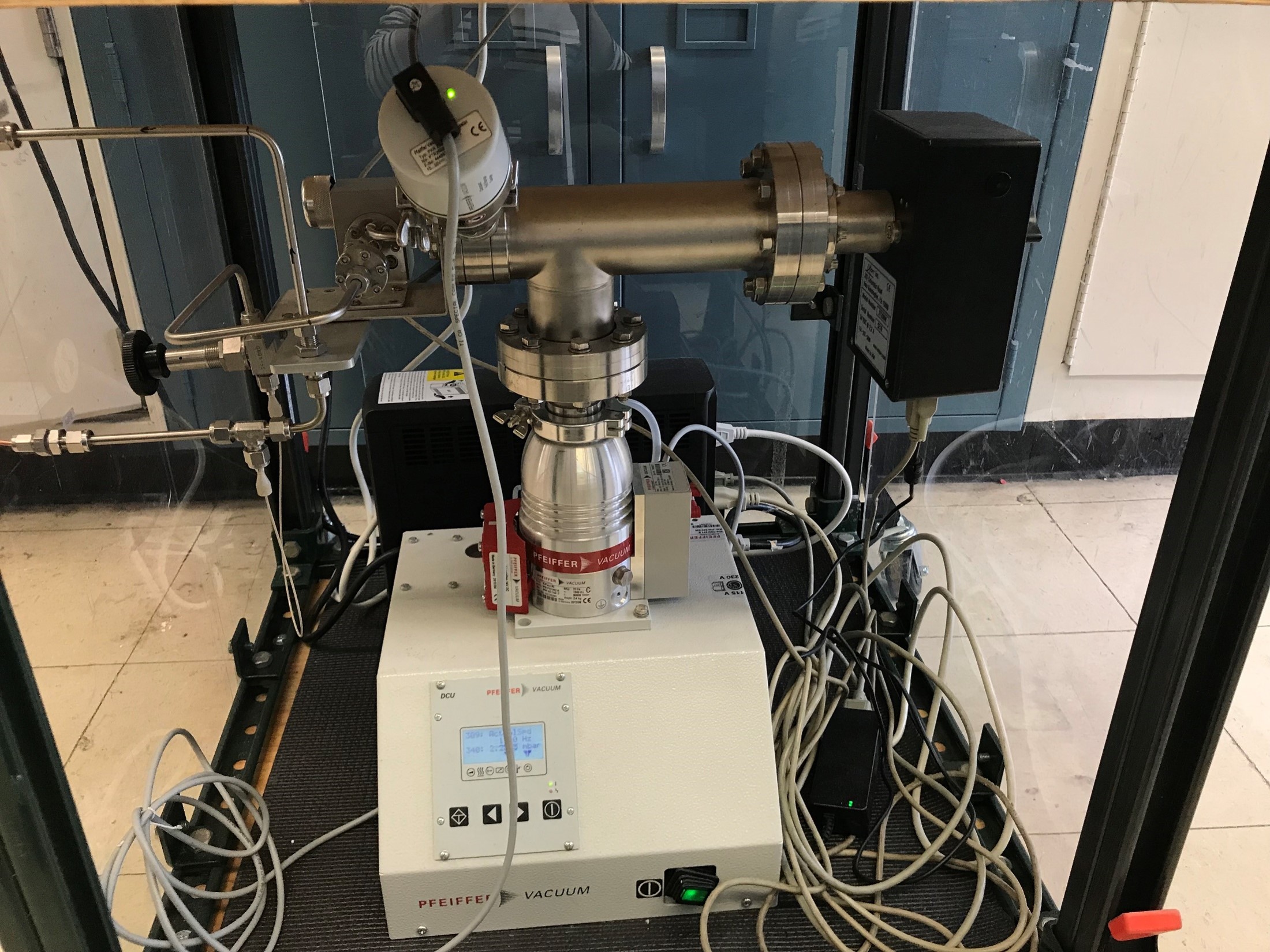

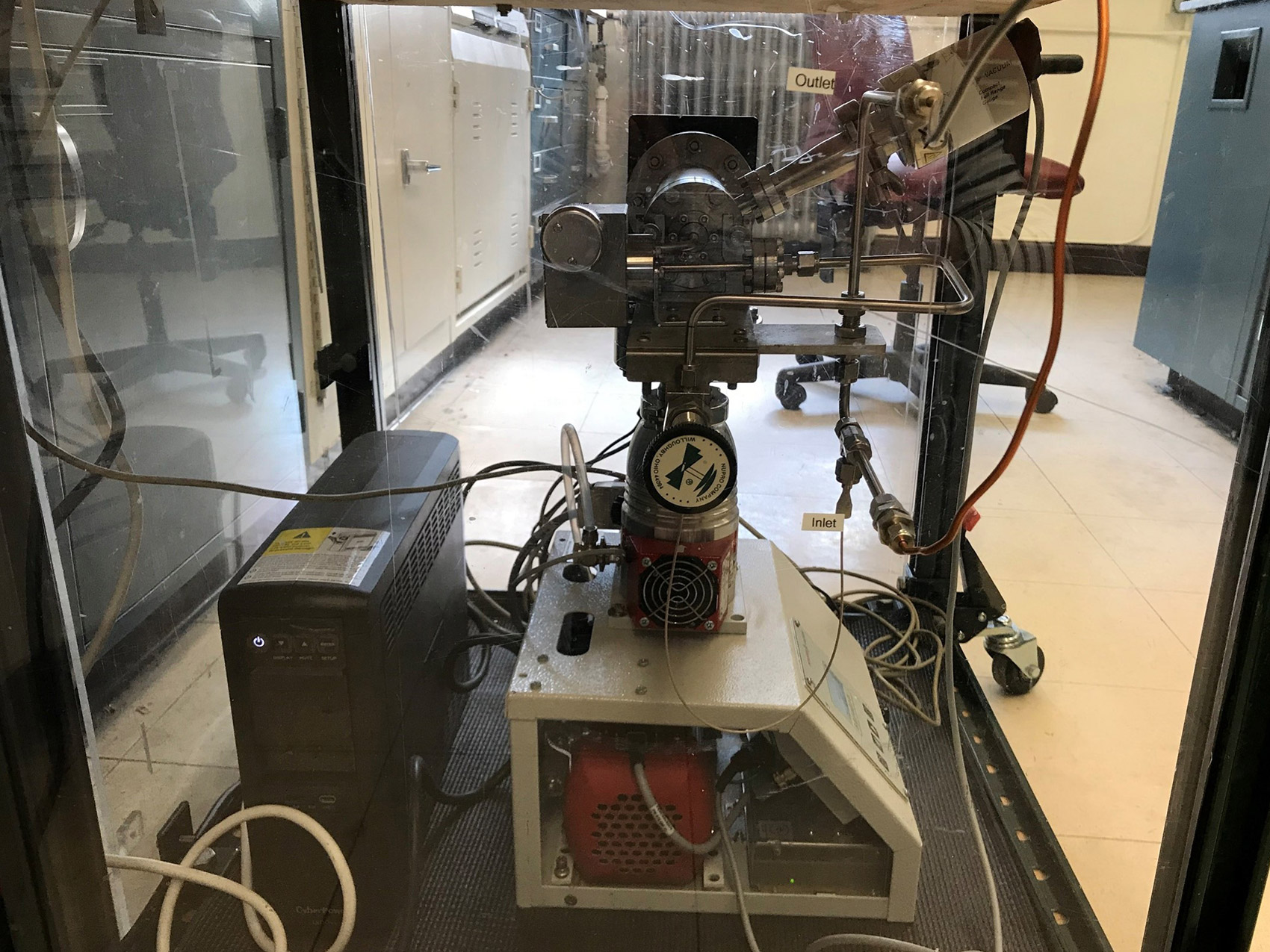

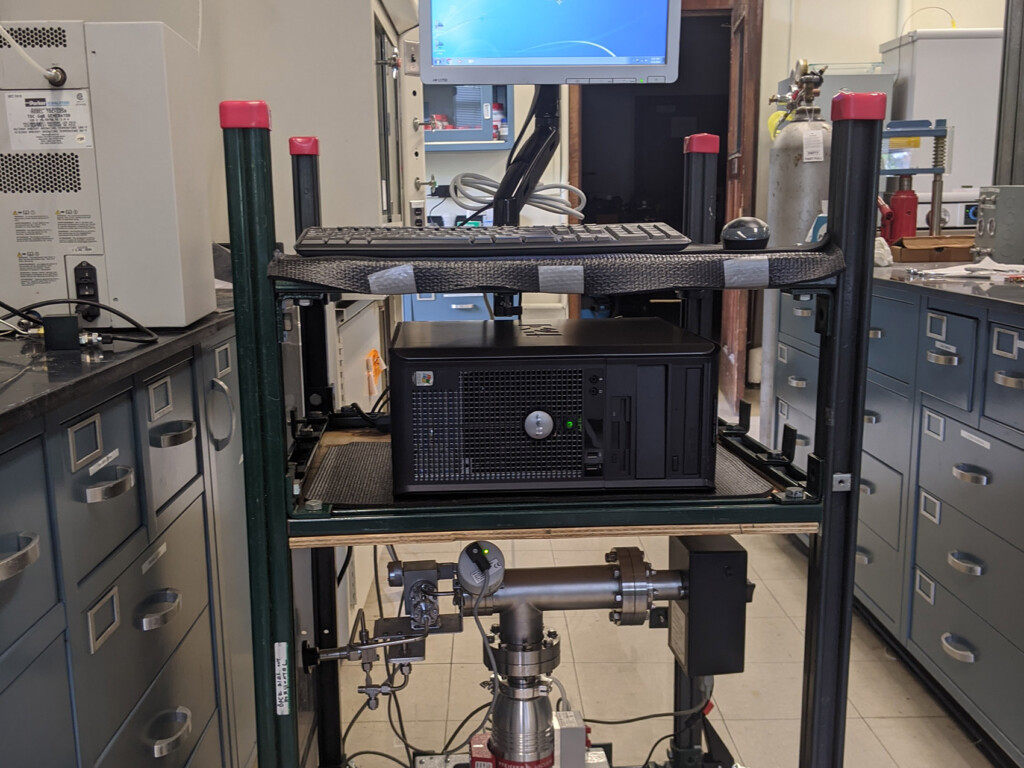

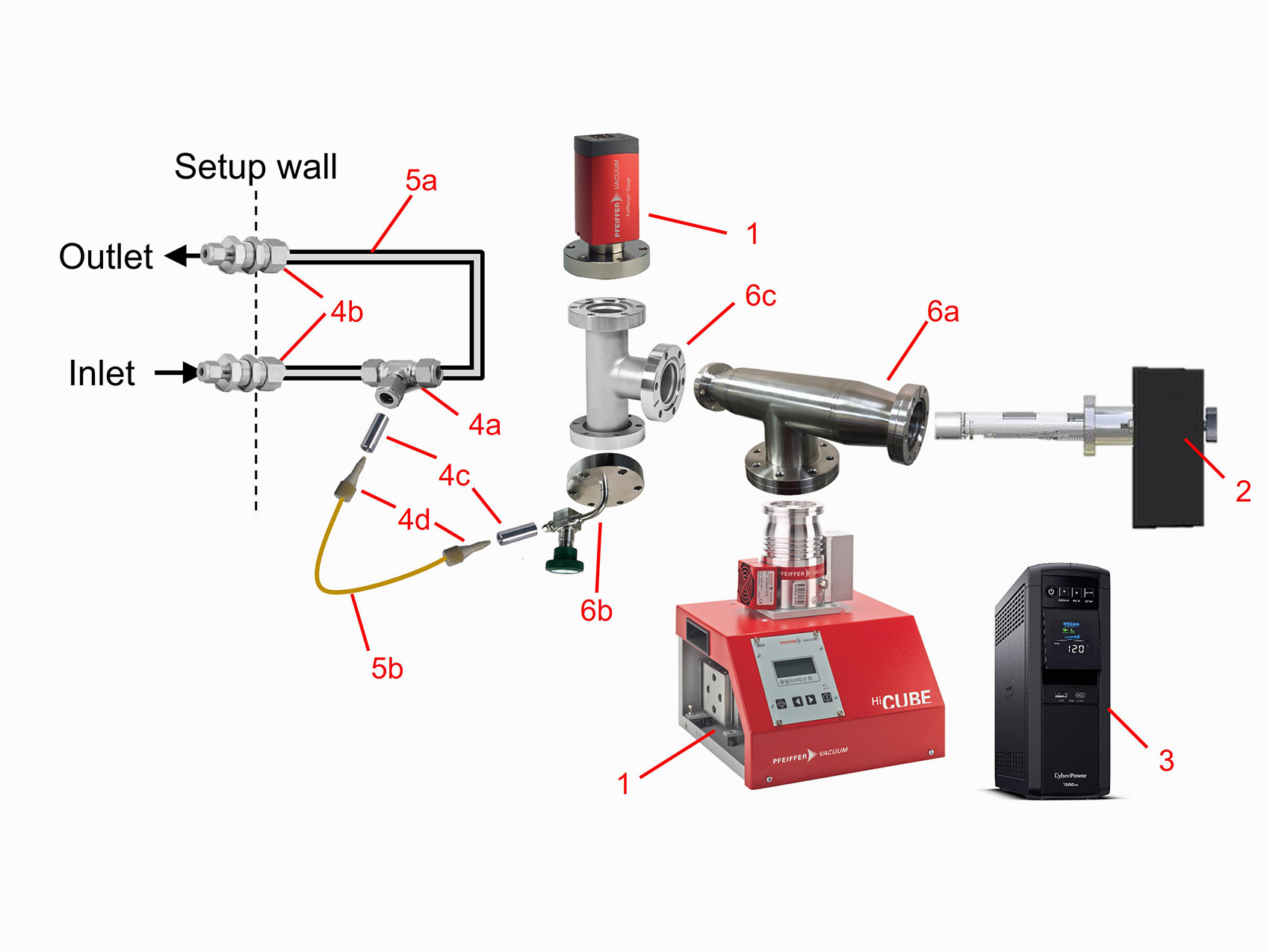

Residual Gas Analyzer

Need to identify products in an effluent reactor stream ? Performing a temperature programmed desorption or surface reaction? Build yourself a residual gas analyzer, on wheels! *Caution* The design below uses 110 V electricity, familiarize yourself with all necessary aspects of electrical work first. Reach out to a licensed electrician if in doubt.

Click images to enlarge:

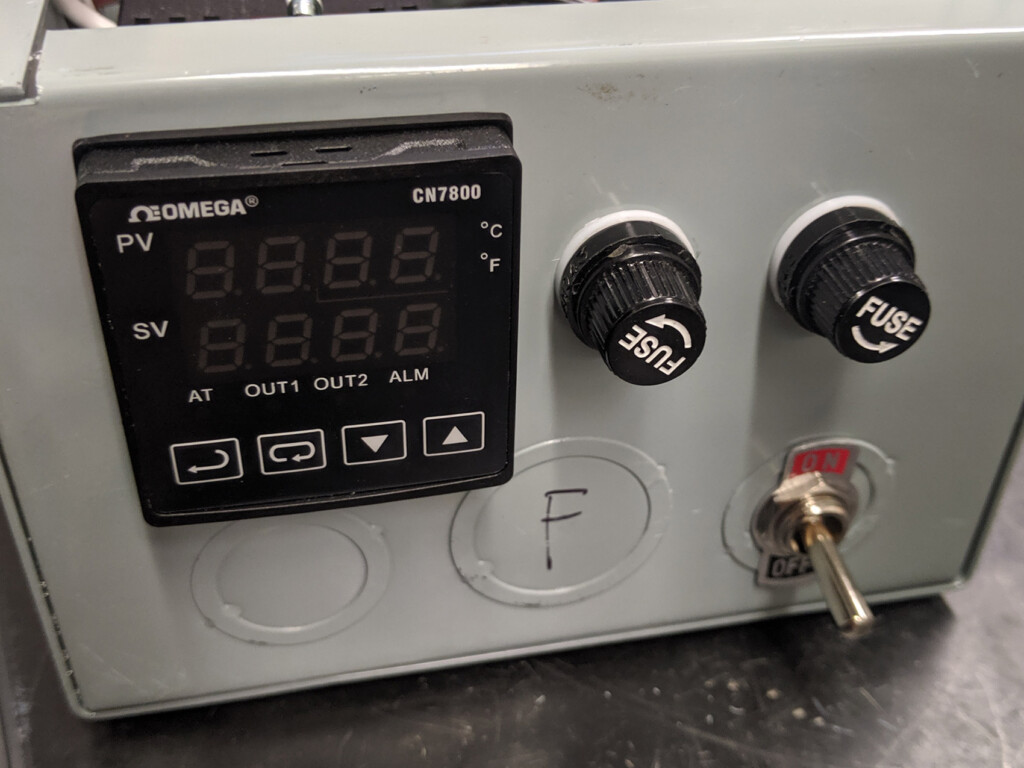

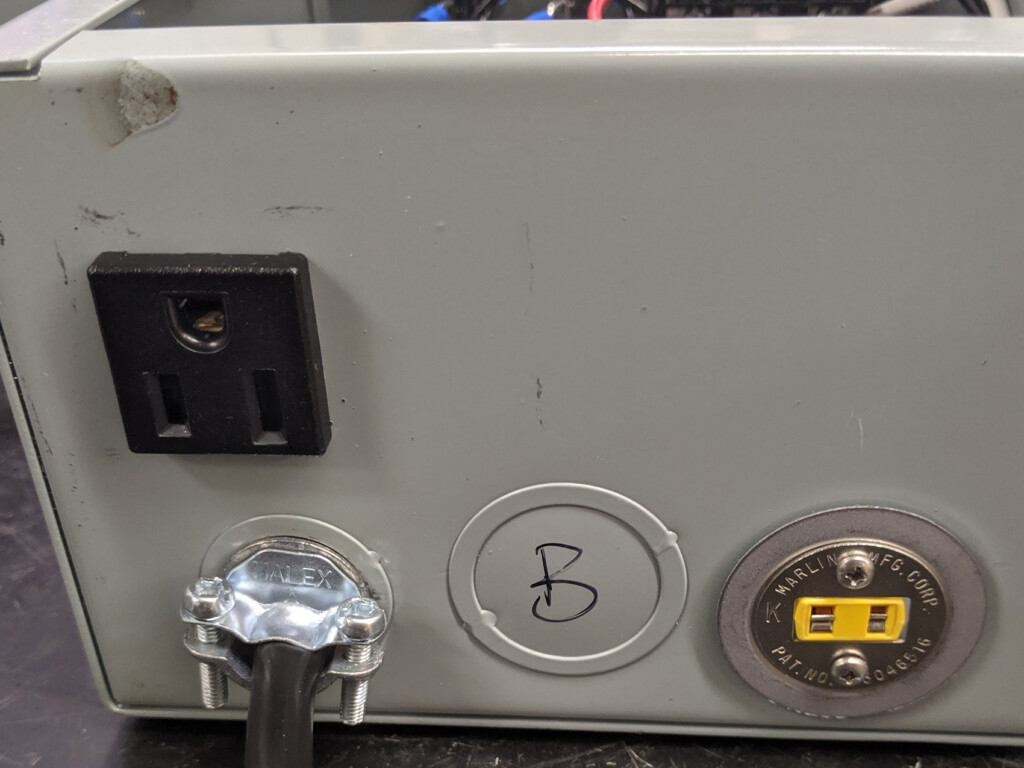

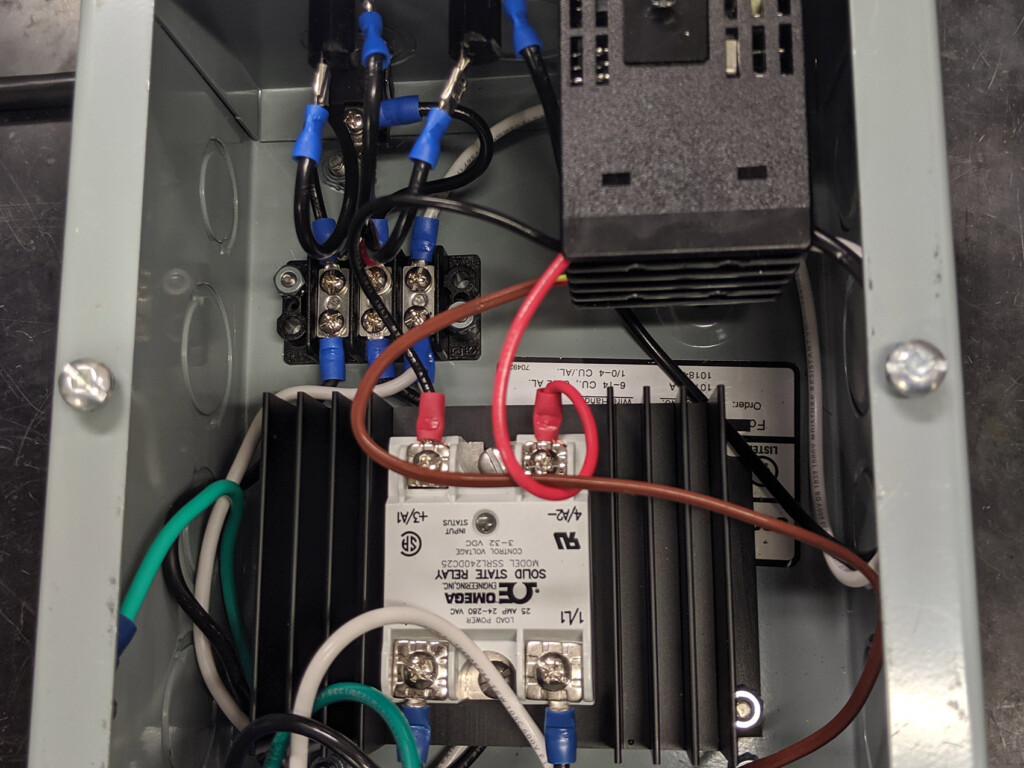

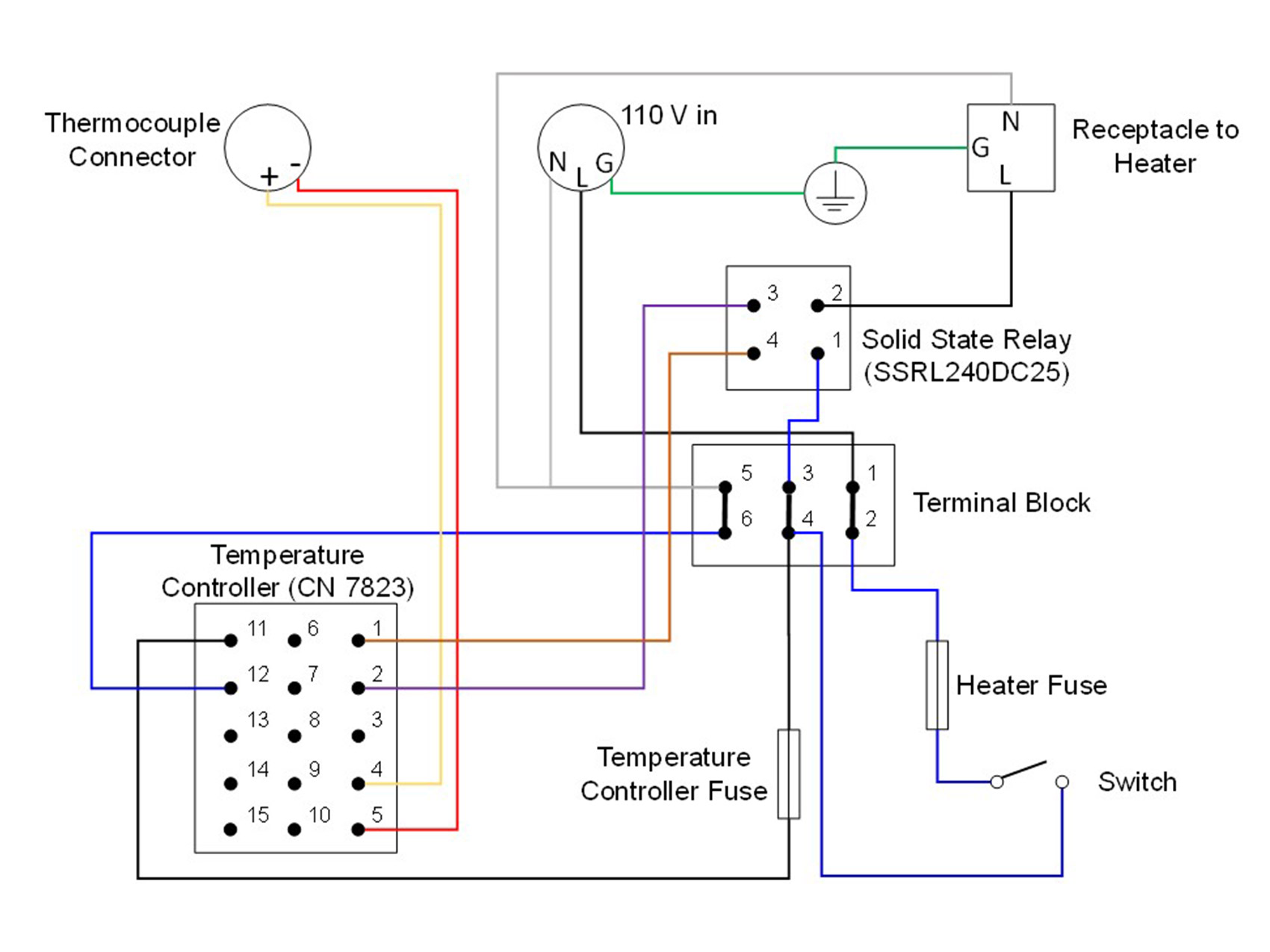

Temperature Controller

When an experiment calls for precise temperatures, a proportional-integral-derivative (PID) temperature controller is a great tool to have. Below is a design for building your own PID temperature controller, using only off the shelf parts. The design allows for a single controllable output, with a heat only functionality, using a type K thermocouple for temperature measurement. *Caution* The design below uses 110 V electricity, familiarize yourself with all necessary aspects of electrical work first. Reach out to a licensed electrician if in doubt.

Click images to enlarge:

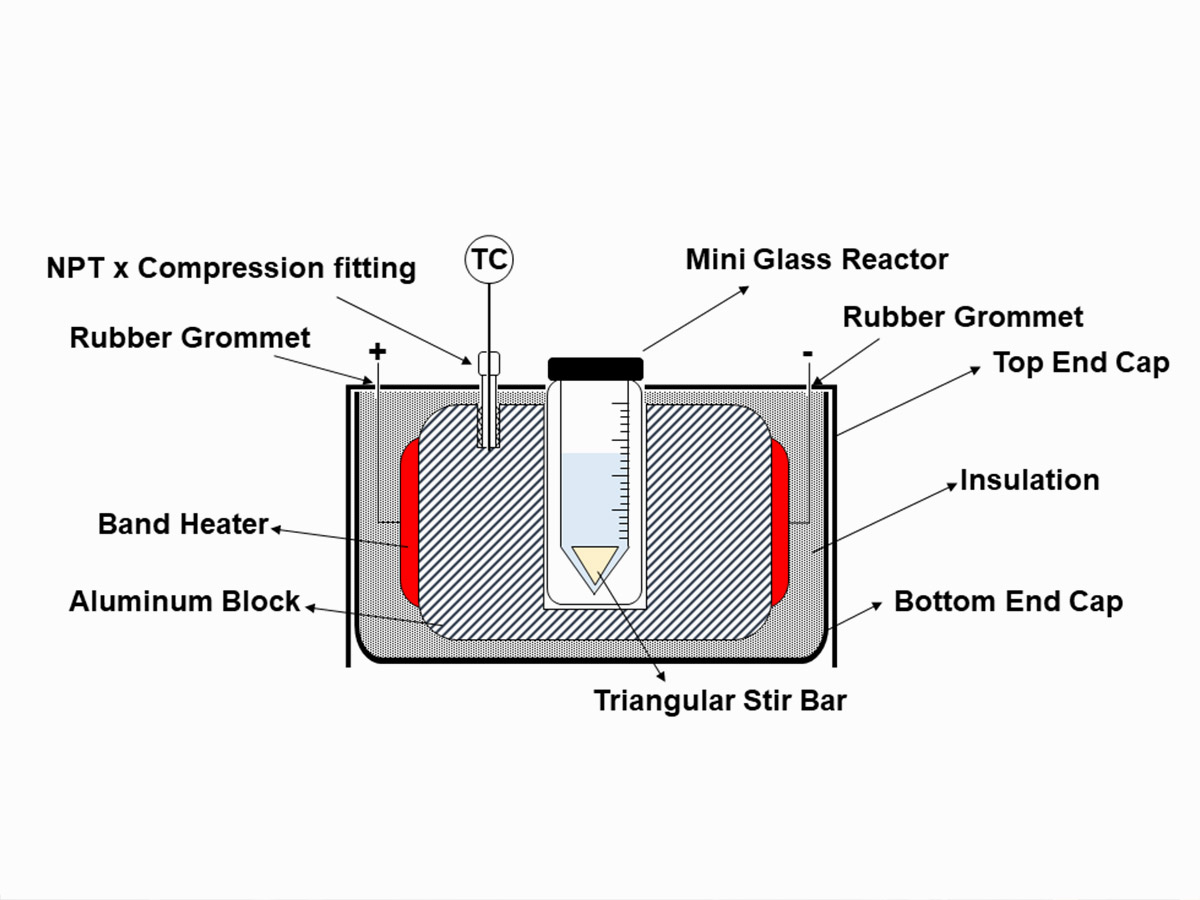

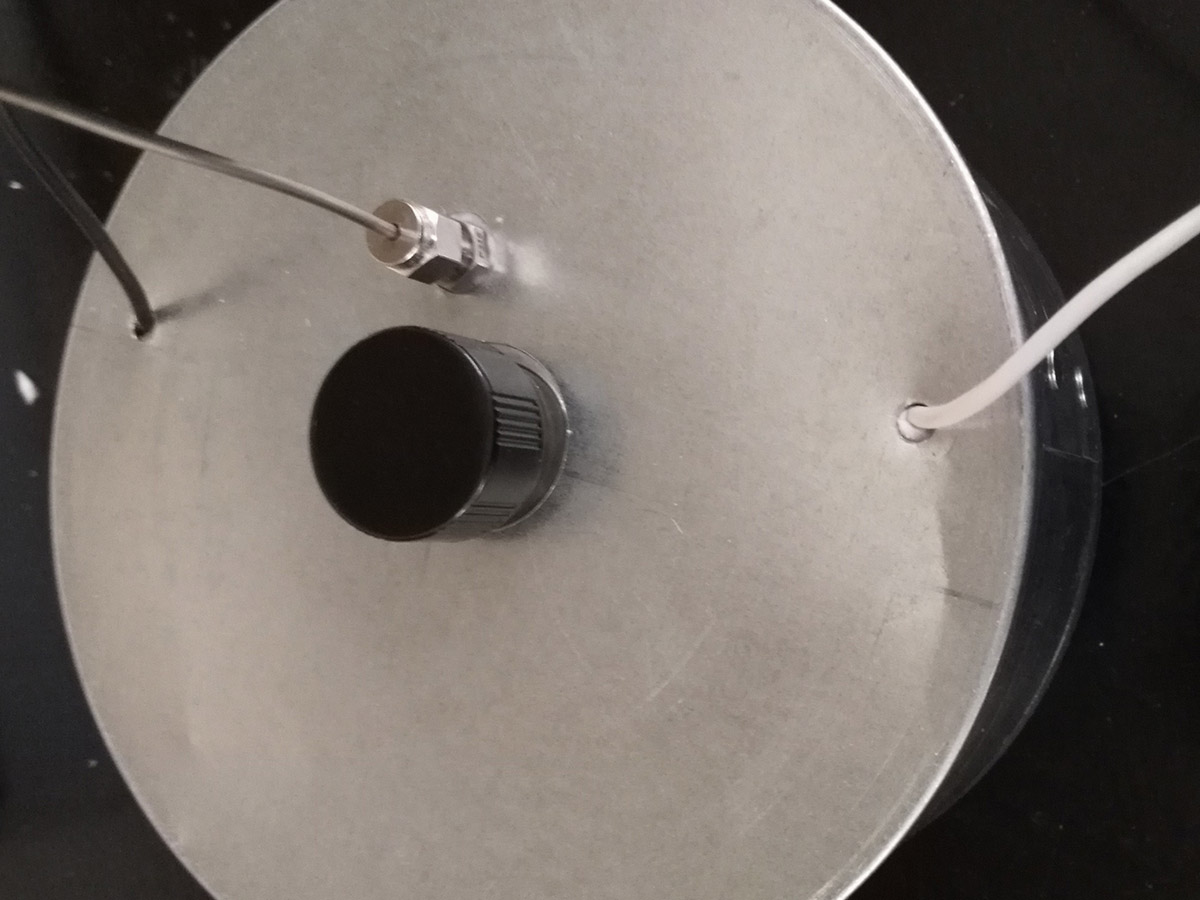

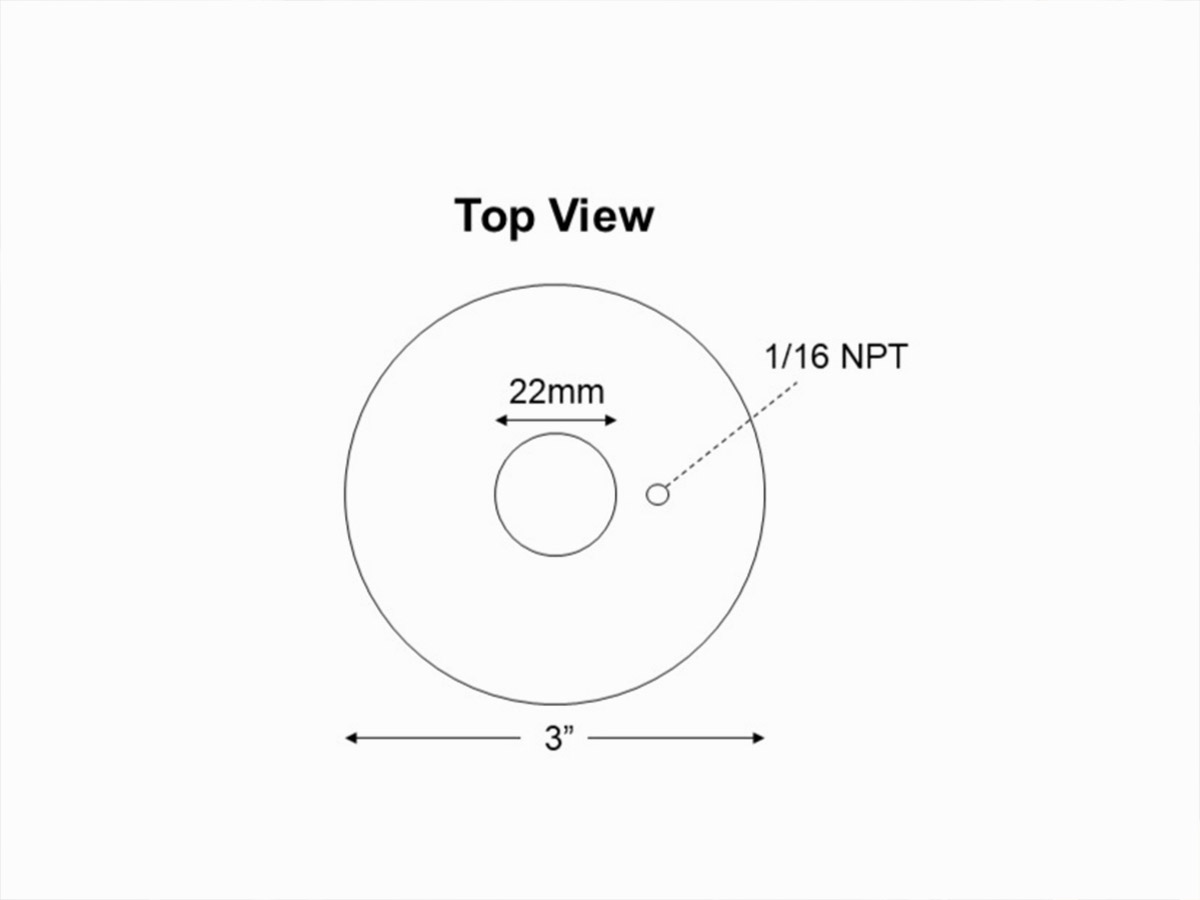

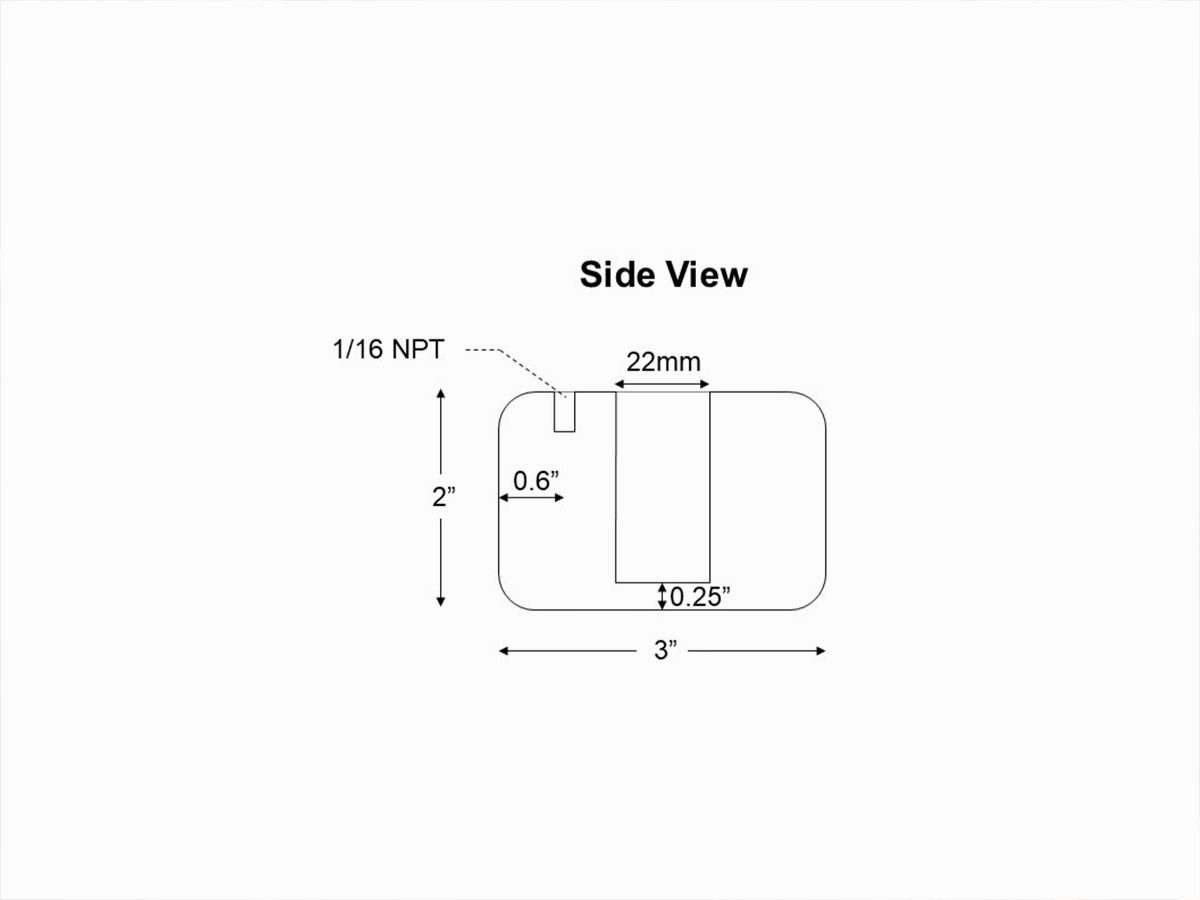

Miniature Batch Reactor

The mini-kickass 9000 provides a simple and cost effective design for a miniature batch reactor, made using only off-the-shelf parts. The reactor consists of a miniature glass vial (5 mL), sealed with a rubber septum and plastic cap, that can be magnetically stirred. The design avoids the use of silicone oil or sand, relying on a mechanically embedded thermocouple to provide accurate and rapid temperature control (coupled with PID temperature controller above). Heating is accomplished using an electrical band heater clamped around an aluminum block, all encased within an insulated environment, providing rapid and accurate heating rates. *Caution* Always be aware of any of the risks associated with chemical reagents and the reaction to be conducted in such a design, as well as chemical compatibility with any of the wetted parts.